| Squak

Mountain Consulting, Inc. |

Monitoring Breathing Air Pressure |

| Please visit these links to our sponsor: Amazon.com |

Please visit these links to our sponsor: Amazon.com |

|

|

|

Monitoring Breathing Air Pressure

PLEASE READ THIS PARAGRAPH FIRST.

THIS IS REALLY DANGEROUS!!!!!!!!!! YOU COULD REALLY HURT YOURSELF!!!!

THIS INFORMATION IS PRESENTED FOR EDUCATIONAL PURPOSES ONLY.

IF YOU WANT TO MEASURE YOUR BREATHING AIR PRESSURE GET PROPER EQUIPMENT FROM YOUR DOCTOR OR MEDICAL PROVIDER.

You take all the responsibility for your use of this information.

There is no warranty, no support, no assurances.

There are errors in this information.

If you hurt yourself and/or others, it's your fault.

If you destroy your equipment or invalidate the warranties, it's your fault.

This disclaimer brought to you by one of the best justice systems on Earth.

This web page copyright © 2006 Squak Mountain Consulting, Inc.

Page 1

Page 2

Page 3

So, my next step was to pick a computer platform and a pressure sensor.

After a little thinking, I started to get pretty picky on the platform. It had to have:

1. programmable processor with 16k+ of memory

2. ADC (Analog to Digital Converter), to process the analog signal from the pressure sensor

3. built-in breadboard, to easily prototype the circuit

4. a way to communicate with a pc (I ended up with RS-232 9-pin serial.)

5. as cheap as possible.

I found what I needed, and more, in the

T89C51 development board from

Futurlec.

It cost only $36, and they added a breadboard to it for another $5.

While I was picking the SBC, I was also figuring out the pressure sensor.

It had to be:

1. the right pressure range

2. small enough to fit on the breadboard (some of the industrial ones are the size of a small computer!)

3. tolerant of the high humidity of exhaled air

4. as cheap as possible

This brought me (after *much* searching) to the Motorola MPX5010DP.

It did everything I needed, and I considered it cheap at $18.50, even though that's 1/2 the cost of the SBC I was connecting it to.

Its innards consist of a high-precision, individually calibrated, strain guage that's coated with silicone gel to resist high-humidity.

Its maximum pressure was only 1.45 psi. So, I went back to my digital pressure guage to measure normal breathing, and found that 1.45 psi would work just fine.

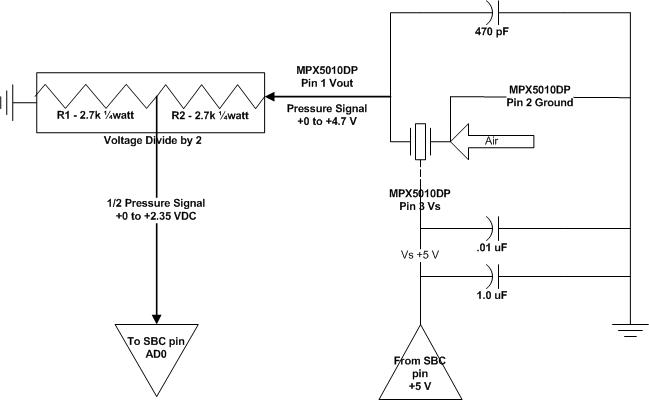

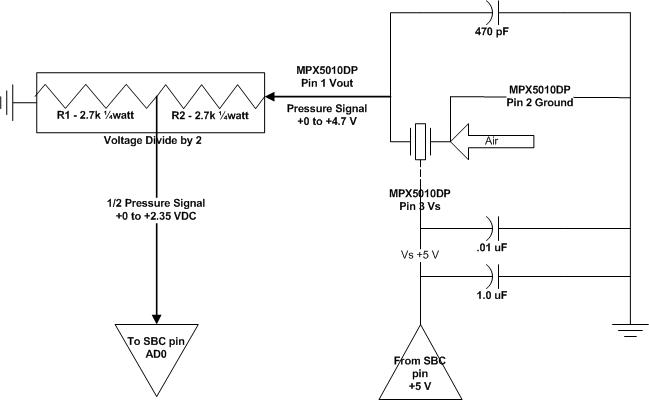

The circuit design was pretty simple.

All I had to do was convert the 4.7 volt signal from the pressure sensor

to the 2.5 volt signal that the ADC required. I also had to deal with various details of power supply, noise suppression, etc, etc...

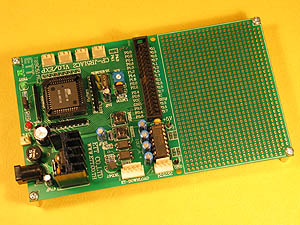

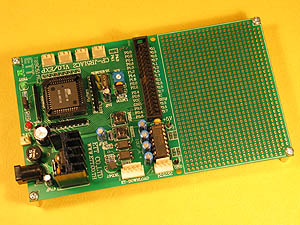

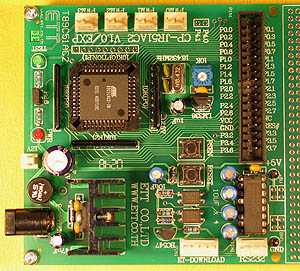

| 1. Here's the basic board, before the breadboard is added. |

|

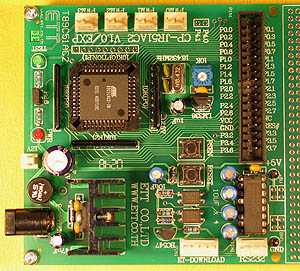

| 2. And a closeup of its guts. |

|

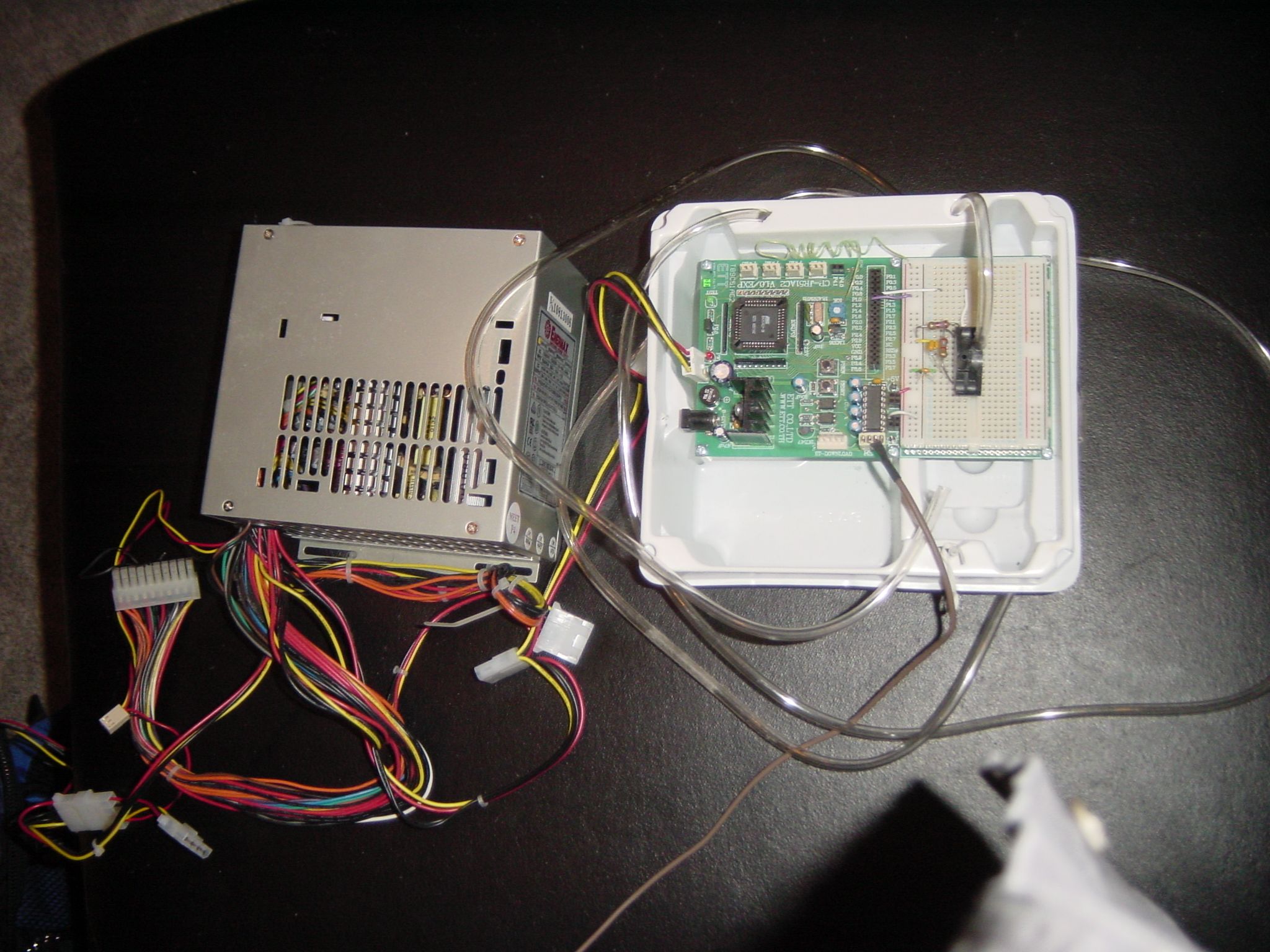

3. Here's my finished circuit. Note the:

..added breadboard,

..plastic base of recycled cell phone packaging

..clear plastic air hose attached to the top of the pressure sensor on the breadboard.

..pc power supply (I could have used a power brick. But, couldn't find one with the right connector...)

|

|

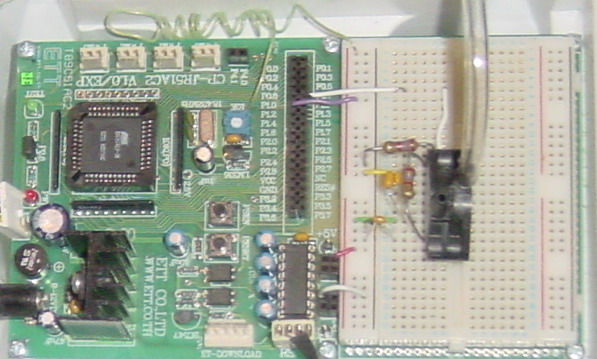

| 4. Here's a close-up of the circuit... |

|

| 5. and a schematic of the circuit |

|

Go To Page 3